|

AUTOZINE TECHNICAL SCHOOL

Engine Construction and Materials Cylinder block

Aluminum alloy block Traditionlly, most mass production engines had their blocks made of cast iron, which is cheap and robust but heavy. Switching to an aluminum alloy block typically saves a dozen kilograms for a 4-cylinder engine and more for larger engines. This benefits the vehicle balance and handling considerably, especially for cars with larger engines. Moreover, aluminum has better thermal conductivity hence better cooling, which suits high-performance engines. In fact, automotive engineers knew the benefits of aluminum block long ago. The 1919 Hispano-Suiza H6 and 1922 Lancia Lambda V4 were among the earliest adopters as far as I can tell. After WWII, many sports and touring cars also employed alloy blocks, such as all Ferraris and Lamborghinis, Maserati A6GCS (1953), Alfa Romeo Giulietta Sprint (1954), BMW 507 (1956) and Lotus Elite 1.2 (1958). That was one of the features that distinguished a high-performance engine from regular ones.

As for non-sporting cars, Rolls-Royce Silver Cloud II surprised the world by introducing an all-alloy 6.2-liter V8 in 1959. However, the true mass production aluminum-block engines have to be Buick's 3.5-liter V8 (1961), which would be better known as Rover V8 soon afterwards, and Renault 16's 1.5-liter A-series engine (1965, also employed by Lotus Europa). By 1979, Mercedes also converted its V8 to alloy block. The all-alloy Peugeot XU engine (used in 205 / 309 etc. since 1982) and Rover K-series engine (1988) made bigger impacts on bread-and-butter cars. BMW's mass-selling M52 straight-six did the same change relatively late in 1994. Ditto General Motors, whose all-alloy LS1 V8 arrived in 1997. Most other manufacturers waited until 2000s and 2010s to make aluminum block standard. The alumium alloy used for casting cylinder block typically comprises of around 90 percent aluminum, 5.5-7.5 percent silicon and small amount of other metals. This guarantees good strength, thermal properties and resistance to corrosion. The alloy is stronger than cast iron by weight but on the contrary by volume, so an alloy block needs thicker walls than cast iron one and additional webs and ribs to strengthen the block. Compacted Graphite Iron (CGI) block Modern turbo diesel engines get more and more powerful. Some even produces more than 100 horsepower per liter. The combination of high turbo boost pressure and diesel engine's high compression ratio, accompanied with increased combustion temperature, puts a lot of stress on the cylinder block, so high that conventional cast iron struggles to withstand, let alone aluminum. Well, you can thicken the block and use extra ribs to strengthen it, but doing so would add considerable weight and size, which is not a desirable solution. Fortunately, in recent years engineers found a better material to do the job: Compacted Graphite Iron (CGI).

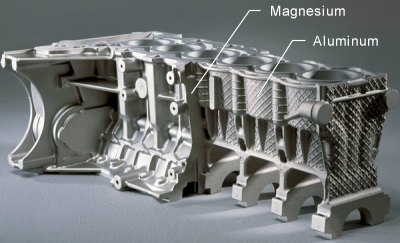

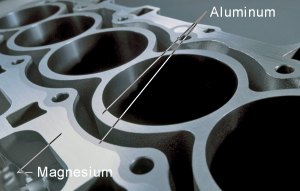

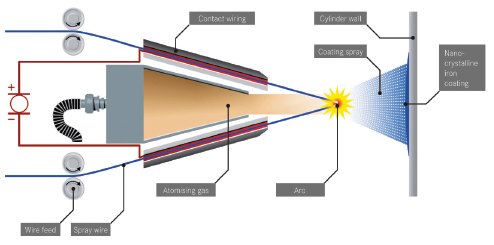

The chief ingredient of CGI is still iron, but it is casted in a special process the requires very precise control, so it is more expensive to build. Under microscope, CGI has shorter and thicker graphite particles than grey cast iron, and this contributes to additional strength. Compared with cast iron, its is 75 percent higher in tensile strength, 40 pecent higher in elastic modulus and twice as resistant to metal fatique. Because it is stronger, a CGI block is typcially 15-20 percent lighter than an equivalent cast iron block. It is also smaller in volume, taking less space in the engine compartment. Today, CGI is widely used on high-performance diesel engines, such as Ford/Jaguar V6, Audi V6 / V8 and VM Motori / Maserati V6. Apart from diesel, Ford also uses it on the Ecoboost gasoline V6 for its F-150 truck, Fusion V6 and some Lincolns. Magnesium-Aluminum block - e.g. BMW N52 To cut weight from cylinder block, BMW once went as far as using the combination of magnesium and aluminum on its N52 straight-six. Magnesium is even lighter than aluminum, but it is not as resistant to heat, mechanical strain and corrosion. Therefore, the N52 used aluminum to construct the "inner block", which included cylinder liners and water passages. Outside, there was a magnesium shell which contained the oil channels and reinforcement ribs. The melted magnesium shell was fused into the aluminum inner block as it cooled, forming a strong structure. The shell also worked as mounting for peripherals such as gearbox and alternator. Thanks mainly to the magnesium-aluminum block, the N52 was 10 kg lighter than its predecessor M54.   BMW used this construction in its naturally aspirated straight-six from 2004 to 2014. Afterwards, the straight-six was converted to turbocharging. The magnesium-aluminum block was considered not strong enough to handle the extra strain, so from N54 it reverted to aluminum block. Closed deck block Most production engines employ open deck block, whose cylinder wall is supported at just 2 points (see picture). It is good for cooling because water passages cover most of the cylinder wall surface. On the downside, the cylinder wall is less rigid and could be distorted under high pressure. Therefore, traditionally motorsport or high-performance engines prefer to use closed deck block, which is more rigid, especially near the cylinder head where the highest pressure is built up. Subaru, for example, used to equip its Impreza STi with closed deck block for homologation purposes.  For most road cars, open deck block is good enough. However, when high-pressure turbocharging is involved, closed deck is prefered. BMW's N54 and N55 turbocharged straight-six used to have their outputs limited to 306 hp because they employed open deck construction. No wonder their high-performance derivative, S55 for M3/M4, had to change to a closed deck block. To save the need for costly upgrade, BMW simply equipped its new production B58 straight-six with closed deck block. Its cooling efficiency is inevitably affected, so the engine is given a better cooling management. Will closed deck become the industrial norm? We shall see. Cast iron liner To make the engine light and fast revving, aluminum alloy is preferred to cast iron for the construction of cylinder block and pistons. However, aluminum is a relatively soft material. When an aluminum piston runs inside an aluminum bore, their contact surface generates high friction and wear, the former prevents the engine from revving high and the latter hurts its durability. In contrast, the contact between aluminum and cast iron has no such problems. Therefore, the early aluminum block engines used cast iron pistons. It was not a good solution because the heavier pistons worked against high rev. An alternative solution was introduced by Chevrolet Vega in the mid-1970s. Its Cosworth-designed all-alloy engine employed iron-coated aluminium pistons. However, the solution was too expensive for mass production thus no one followed suit. A much cheaper solution is cast iron liner. A thin (about 3 to 5mm) cast iron tube is inserted into the cylinder bore and provide a smooth surface for the piston to run inside. Inevitably, it adds some weight and thickness to the cylinder wall, reducing the advantages of aluminum block, but it is a good compromise for cost and benefits thus is widely used in mass production all-alloy engines. Nikasil Nikasil was first introduced to the road car world by Porsche 911 RS 2.7 in 1973, since then it has been the first choice for high-performance Porsches, Ferraris, McLaren F1, BMW M-power V8 and V10, Lotus Esprit, Jaguar AJ8... Instead of cast iron liner, Nikasil treatment coats a thin layer of nickel-silicon carbide to the inner surface of aluminium cylinders. Silicon carbide is very hard, durable and, most important, low in friction. It enables the aluminum piston to run smoothly, enhancing rev and power. In Nikasil process, nickel solution is used to dissolve silicon carbide and then electroplated to the cylinder bore. The piston rings will rub off the exposed nickel and leave the smooth silicon carbide surface. It also has better thermal conductivity than cast iron liner thus suits high-performance engines. Another advantage is, the Nikasil layer is just about 0.1mm thick, so the spacing between adjacent bores can be reduced considerably, making the engine smaller and lighter. In case an engine runs out of space for enlargement, using Nikasil in place of iron liners allows the bore to be enlarged, saving the need of developing a new engine. In fact, the aforementioned 911 RS 2.7 would not have been made without Nikasil. On the downside, Nikasil is pretty expensive to manufacture as it involves wet process, thus it is rarely used on affordable cars (Ford Puma was a rare example). Moreover, the coating could be damaged by high-sulphur fuel which was still widely available in the US market until recently. Alusil Alusil is a cheaper and more reliable solution. It is not a coating but a kind of high-silicon aluminum alloy, consisting of about 78% aluminum, 17% silcon plus some copper and magnesium. The alloy surface is treated through a honing and lapping process and chemical etching that exposes a hard silcon precipitate, thus rendering the abundant silcon particles on the aluminum surface, which reduces friction and wear. Compared with Nikasil, Alusil is slightly less good in thermal conductivity, friction and weight, but it is much cheaper to build and not subjected to sulphur damage. This is why BMW changed its all-alloy mass production engines from Nikasil to Alusil from 1996. The material is also used in Volkswagen group's V6, V8 and W12 engines. Fiber-reinforced metal (FRM) Fiber-reinforced metal (FRM) cylinder sleeve is a solution introduced by Honda in 1988. Both its cost and efficiency are halfway between cast-iron liner and Nikasil coating. A fiber-based material in the form of cylinder sleeve is first inserted to the die of the block. Melted liquid aluminium is poured into the die and integrate with the fiber sleeve. Then the cylinder wall is machined to the desire bore dimension, leaving only 0.5 mm thickness to the fiber sleeve which covers the cylinder wall. The FRM surface has lower friction than iron liner, thus improves rev and power. Moreover, the fiber sleeve reinforces the block, allowing the distance between adjacent bores to be reduced yet maintaining mechanical strength. Honda used FRM for its high-revving engines on NSX 3.2, S2000 and Prelude 2.2 VTEC. Twin-Wire Arc Spray (TWAS) In 2006, Mercedes introduced its Twin-Wire Arc Spray cylinder coating technology on CLK63 AMG. The 6.2-liter V8 used an aluminum block without cylinder liners. Its bore was coated with a thin layer (0.1-0.15mm) of nano-crystaline iron by means of the TWAS process. In this process, twin iron and carbon wires are heated up to 2000°C, vaporized and sprayed onto the cylinder bore surface. After honing will result in a mirror-like finish with low friction. The coating is durable and resistant to sulphur pollution. Since then Mercedes kept improving the production process and has it renamed to "Nanoslide".  Mercedes is not the only one to use arc spray coating. The 2007 Nissan GT-R used a similar technology called "Plasma transferred wire arc spraying" on its V6. However, Mercedes remained the leader in this field as it has shifted countless of AMG 6.2-liter and 4.0-liter V8 with this technology. More recently, its applications expanded to also V6 diesel and V6 petrol. |

||||||

|

||||||

| Copyright© 1997-2017 by Mark Wan @ AutoZine |