|

AUTOZINE TECHNICAL SCHOOL

Volkswagen VR and W-engines Born in 1991, Volkswagen's narrow-angle VR-engines are probably the most special engines in production (save Wankel engines, of course). Its concept was inspired by Lancia, which used narrow-angle V4s since 1922, and especially the twin-cam version on Fulvia HF. While V4 had little use on modern cars, Volkswagen developed the idea into VR6 and V5 for its mass production cars which had no space for conventional 5 or 6-cylinder engines. That was a clever solution. Under the leadership of Ferdinand Piech, who was known for desire of large engines and technical innovations, the VR6 was developed further into W-engines with 8, 12 or even 16 cylinders. Consequently, the VR and W-engines became a big family covering a variety of cars, ranging from Golf to Bugatti. This must be the most heavily invested engine family in history. VR6:

1st generation (12-valve)

6 cylinder engines, no matter inline-6 or V6, are inherently smoother than 4-cylinder inline engines because all the first order and second order forces can be balanced. However, most small cars do not have the space to accommodate a 6-cylinder engine. To use space more efficiently, nearly all small cars employ front-engined + front-wheel-drive configuration, or FF. This means, the engine, clutch, gearbox and differential are all installed up front accompanied with ABS pump, servo, air-conditioning, battery and steering mechanism etc. Therefore, it is not easy to fit a six-cylinder engine into the engine compartment, especially straight-six which is simply too long because the gearbox and clutch has to be installed right beside it.  V6 is much shorter, but its

width (excluding accessories) is at least doubled from inline-six, so

it

engages a lot of length of the engine compartment. Moreover, the hot

exhaust pipes at either side of the Vee prevent any other

components from placing too close, thus need more clearance. Therefore,

most small cars fail to accommodate a V6 in their engine compartments. V6 is much shorter, but its

width (excluding accessories) is at least doubled from inline-six, so

it

engages a lot of length of the engine compartment. Moreover, the hot

exhaust pipes at either side of the Vee prevent any other

components from placing too close, thus need more clearance. Therefore,

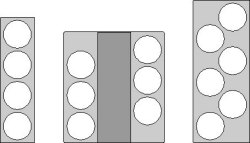

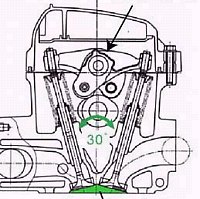

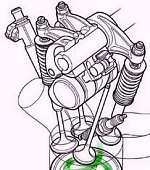

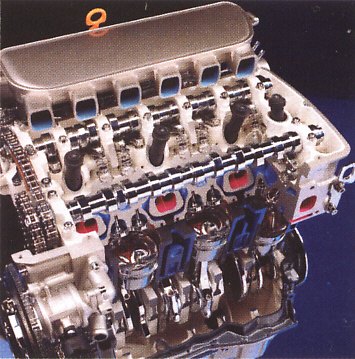

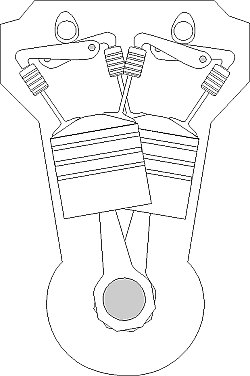

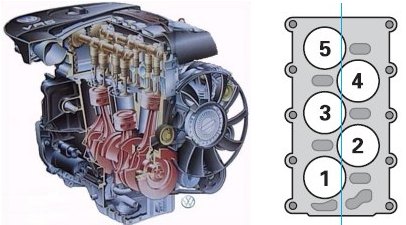

most small cars fail to accommodate a V6 in their engine compartments.In 1991, a breakthrough was achieved by Volkswagen. It developed a narrow-angle (15°) V6 displacing as much as 2.8 litres and installed it to the 3rd generation Golf. As it combined the features of both V-engine and inline engine, Volkswagen called it "VR6", in which R stands for Reihenmotor, the German word for "inline motor". As seen in the picture, the VR6 was really very compact, nearly as narrow as an inline engine and not much longer than a straight-4. It could be fitted into many small cars, including Polo (which didn’t because of price reason). It was also supplied to Mercedes-Benz V-class, whose short front end could not fit Mercedes’ own V6. The VR6 could be made as narrow as 15° without overlapping the cylinders because adjacent cylinders are widely spaced from each other, as shown in the following picture. This inevitably increases its length but it is still shorter than a 5-cylinder engine. For most small cars this is short enough.

Asymmetric Configuration Another feature of VR6 is very important for our further study of the 24-valve VR6 and W-engines: the VR6 is asymmetric.

Valve Gear The first generation VR6 had 2 valves per cylinder, single overhead camshaft (SOHC) serving each bank just like any conventional 2-valve V6s, although the 2 camshafts were positioned so close that they looked as if a twin-cam design. Cylinder Head / Block In many ways the VR6 is constructed like an in-line engine. Thanks to the close proximity of the two cylinder banks, they could share a common cylinder head. As a result, VR6 is not only smaller but also lighter than conventional V6. On the down side, its crankshaft is also constructed like that of a straight-6. Each cylinder is served with its own crank pin and counter weights, and the crankshaft is supported on 7 main bearings. In contrast, a V6 has half the number of crank pins and only 4 main bearings. This means the VR6 is no cheaper to build than a V6. VR6:

2nd generation (24-valve)

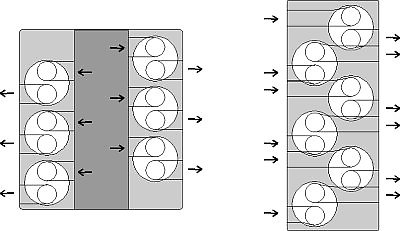

When 4-valve engines became the industrial norm by the early 1990s, Volkswagen’s VR engines (both VR6 and V5) still relied on SOHC 2-valve heads until the arrival of the second generation VR6 in July 1999. You might wonder why it took 8 years to bring the VR6 a 4-valve head. In fact, it had some technical difficulties to overcome. Technical Difficulties When I heard the rumour about the 24v VR6 about 2 years before its launch, the first question came into mind was: how to fit 4 camshafts into the small piece of cylinder head? It seemed virtually impossible, especially that some space has to be left for replacing spark plugs. If not having 4 camshafts, then it must be an SOHC design serving 4 valves per cylinder, just like many Japanese cars, say, Honda and Mitsubishi, did at the time. However, SOHC 4-valve is not an ideal design. Firstly, it puts 3 or 4 elegant, narrow cam lobes to each cylinder, thus was relatively complex. Secondly, the ideal position of a rocker arm/cam set is exactly vertical above the valve it actuates, otherwise the movement may generate a lateral force which wastes power, introduces friction and eventually drags down the rev. For SOHC 4-valve, because the ideal position of the rocker arms for intake and exhaust are exactly the same, a small distance shift is introduced to one of them or both of them, thus results in the aforementioned drawback. That is why all the high-performance Honda (from Civic SiR to Type R) employed DOHC, wheareas SOHC design was used in its cheaper mass production cars.

But the most important reason that makes SOHC 4-valve undesirable is that it does not allow the adoption of cam-phasing variable valve timing. Think about it: if you shift the camshaft 20° in advance, the intake valves will open and close earlier, but so will the exhaust valves. This results in little or no gain in performance. How did Volkswagen overcome these problems? Volkswagen's Solution

If you still remember, a feature of VR6 is that it is asymmetric. This enables the exhaust valves in both bank remains in a distance accessible by a common camshaft. Without the narrow angle and the asymmetric configuration, the share of camshaft would have been impossible.

If it were a

conventional V6, it would have needed 4 camshafts and 4

cam-phasing actuators to implement the same functions. The VR6 needs

just half of them. It is interesting to see the 24-valve VR6 has the

same number of camshaft

as its 2-valve predecessor. This is one of the most remarkable

inventions. V5 engine Officially, Volkswagen never called its narrow-angle V5 as VR5, but it came from the same VR family. The 2.3-liter V5 was essentially a VR6 with one cylinder removed. It seems to be an unbalanced configuration, but its narrow V-angle (only 15°) and its counter-weighted crankshaft let it worked remarkably like an inline-5 engine. A dual-mass flywheel and vibration damper took care of the remaining vibration.  Like VR6, the original V5 was served with SOHC and 2 valves per cylinder. Later on, it was upgraded to DOHC and 20 valves, lifting output from 150 to 170 hp. However, the V5 was not widely used in the group. It was eventually replaced with a conventional inline-5, which was also compact enough to be fitted into Golf and Jetta, and was cheaper to build. W12 engine

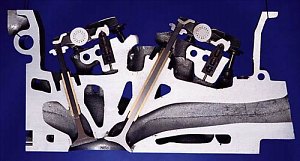

Having learned VR6, it is not difficult to understand W12. As Volkswagen said, the W12 engine first shown in the mid-engined W12 supercar was virtually a combination of two VR6s. This was confirmed by its 5.6-litre displacement. It was constructed by mating two 15° VR6 in an inclined angle of 72°. In fact, the W12 was the earliest VR engine family member to showcase 4-valve head, although that car was never put into production. Measuring just 521mm in length, it was a lot shorter than conventional V12s.    The W-configuration would have been never realised if not the invention of VR6. Audi had been researching its own W-engines for years (even showed it on the Avus concept car, but the engine was fake) but eventually terminated the project. I remember sources said it failed to solve the exhaust/ventilation problems. It was basically formed by 3 banks of 4-cylinder in-line. The problem was how to run the exhaust pipe for the center bank without overheating the surroundings and without wasting too much space. Volkswagen’s approach had nothing to do with the experience of Audi, because the Volkswagen unit was derived from the VR6 which was already under development since the 1980s. Benefited by the asymmetric design of VR6, exhaust of the left VR6 ran out from the left side, while exhaust of the right VR6 ran out from the right side. Therefore the exhaust system was just the same as any V-engines. The only short-coming of W-engines is that they require very thin connecting rods, as the crankshaft is much shorter than that of a V-engine. While the VR6 used con-rods with 20mm thickness, the W-engines ran with 13mm ones. This prevented it from becoming racing engines. Tight cylinder heads may also limit its breathing and ventilation. W16 engine

W8 engine

W18 engine

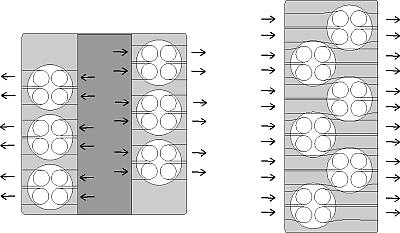

As 18 is

not dividable by 4, you know the W18 was not derived from VR engines.

In fact, it followed the old Audi philosophy of mating 3 banks of

6-cylinder, driving a common crankshaft. The drawback was: among the 3

banks there are 2 large Vee angles, 60° each,

hence a total of 120°. For comparison, the W16 spans just 15/2 + 72

+

15/2 = 87°, therefore the W18 is a lot wider. In terms of length,

the W16 has the same length as a VR8, that is, about the length of

5-cylinder. The W18 is as long as an inline-6. As 18 is

not dividable by 4, you know the W18 was not derived from VR engines.

In fact, it followed the old Audi philosophy of mating 3 banks of

6-cylinder, driving a common crankshaft. The drawback was: among the 3

banks there are 2 large Vee angles, 60° each,

hence a total of 120°. For comparison, the W16 spans just 15/2 + 72

+

15/2 = 87°, therefore the W18 is a lot wider. In terms of length,

the W16 has the same length as a VR8, that is, about the length of

5-cylinder. The W18 is as long as an inline-6.As seen in the picture, the W18 used by Bugatti EB218 concept car was very big and complex. Two of the banks mated like a conventional 60° V6 while the remaining bank laid down to horizontal level. Complex intake and exhaust manifold occupied the space between the banks. (Note that the exhaust pipes were not fitted to this prototype, otherwise it would have looked even more complex.) Obviously, W18 was not as clever as W16. Although it had not much problem to fit in the jumbo-size Bugatti saloon, it seems to offer few benefits. Was it more powerful than a V12 could achieve? No. Was it smoother than the theoretically ideal V12? No. Was it shorter than a V12? No. Was it narrower than a V12? On the contrary. Was it cheaper to be built ? Never. No wonder Volkswagen eventually terminated the W18 project. It was never put into production. The Rise and Fall of VR and W-engines The first VR engine was launched in 1991 on Golf Mk3 VR6. It displaced 2.8 liters and produced 174 hp, transforming the Golf into a premium performance car in the same breath of BMW 3-Series. Shortly afterwards, it was upgraded to 2.9 liters and 190 hp for use in Corrado VR6. Both VR6s were known for smoothness, linear power delivery and sound unrivalled by the turbocharged fours used by their rivals. In 1999, the VR6 evolved to 24 valves and 204hp for use in Golf Mk4 V6 4motion, in which it mated with 4-wheel-drive for the first time. 2001 saw the limited edition Beetle RSi showcasing the larger, 3.2-liter version. From 2002, the 3.2-liter VR6 was adopted on Golf Mk4 R32 and Mk5 R32, which offered 240 and 250 hp respectively. Naturally, the R32 sat atop the four-cylinder Golf GTi as a premium choice. Elsewhere, Seat Leon Cupra 4 was given the 2.8-liter 24V VR6. From 2003, Audi A3, TT Mk1 and Mk2 also got the service of the 3.2-liter VR6. All these cars were derived from the Golf platform. The 2.3-liter V5 debuted on the 1997 Passat and 1998 Golf Mk4, initially with 10 valves and 150hp but later on evolved to 20V and 170hp. It served also sister cars Bora (Jetta) and Seat Toledo. The Volkswagen group did not stop developing conventional V engines though. In fact, Audi kept using its own V6 and inline-5 engines for longitudinal-engined applications. The VR engines were preferred for transverse-engined applications because they could fit the tight engine compartments of FF cars easily (the only exception was Phaeton, which installed the 3.2-liter VR6 longitudinally). This allowed the group's premium models to provide the power, torque, smoothness and sound of big engines, which was not possible on small turbocharged motors. However, from the mid-2000s EU started tightening CO2 regulations. Volkswagen found it difficult to sell small cars with big engines. Meanwhile, turbocharging technology progressed a lot in both response and refinement. Therefore, from Golf Mk6, Volkswagen decided to drop the VR6 and V5 in favour of turbocharged four. The VR6 survived a little longer on Passat Mk6, including its 3.6-liter version dubbed R36, and the 2008 Skoda Superb. By 2015, only the North American Passat still used the VR6. The sophisticated W8 was used only on the 2001 Passat W8. It was more expensive to build than the conventional V8s used by Audi thus was difficult to find another application. A technical achievement, but made little commercial sense. Volkswagen Phaeton and the first 3 generations of Audi A8 employed the W12, displacing either 6.0 or 6.3 liters and producing 420 to 500 hp. By the time the A8 Mk3 is replaced, both brands no longer use W12. Nevertheless, W12 will continue to survive in the luxury cars of Bentley, whose high prices and low production volume made possible. Since Bentley employs permanent 4WD system, the compact W12 fits well into the nose of the car without worsening balance too much, something not possible with a V12. In 2016, Bentayga SUV introduced a new generation W12 with direct injection and cylinder deactivation to improve emission and fuel consumption. Hopefully this will take the W12 well into the next decade. Meanwhile, the 8-liter quad-turbo W16 still serves Bugatti. Since 2005 its output has been improved from 1000 to 1500 horsepower, which is still the most powerful engine in the world. The VR family was originally conceived for compact cars. Today, it survives on only large luxury cars. Life is full of unexpected. |

|||||||||||||||||

| Copyright© 1997-2017 by Mark Wan @ AutoZine |