Adaptive damping

Ferrari and Maserati are

the

keenest users of adaptive damping. The former's Mondial T, F355, 456GT,

550M, 360M and the latter's Shamal, Quattroporte and 3200GT all

employed

electronic adjustable dampers in the suspensions. In most of the time,

the damper is in "soft" setting to benefit ride comfort. In case the

car

goes in action, it is set to "stiff" mode for stable handling and

minimize

body roll.

The mechanism is

usually

very simple. By varying the total area of valves area within the shock

absorber, different rate of damping can be obtained. Therefore the

shock

absorber alone is able to implement the adaptive damping.

|

Ferrari

Mondial T - the

earliest Ferrari to have adaptive damping. |

Ferrari's earliest

system was

launched in Mondial T. It required the driver to select the rate of

damping

among 3 settings - soft, intermediate and hard. Later, in 456GT and

F355's

systems, computer decided the setting automatically. Sensors were

employed

to measure the longitudinal acceleration, lateral acceleration, speed,

brake pressure, load and steering angle. Via analysing these data, the

computer knew the driver's intention - to go fast or to travel

leisurely.

Then decide the most suitable damper setting.

It looks great, but

the effectiveness

is quite limited. Firstly, it can just vary the damping rate, not the

spring

rate and anti-roll bar function. Secondly, individual wheel or axle

cannot

be set according to need. All four wheels always run on the same

damping

setting. Thirdly, it seems that until now all the designs still react

slowly,

therefore they are employed to deal with the changing driving style

(which

is more consistent) rather than the change of road condition (which is

fast-changing and unpredictable).

Semi-Active Suspension

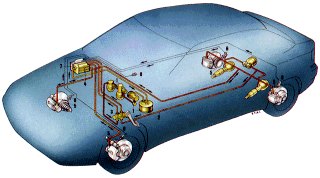

Citroen XM's Hydractive

|

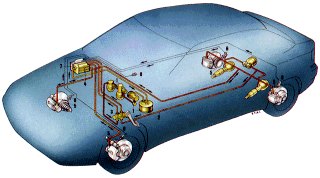

XM's

Hydractive system.

Note that there are totally 3 spheres in the rear axle. All the

suspensions

are interconnected with high-pressure hydraulic which is supplied by

the

engine-driven pump. The front spheres are not shown in this

picture. |

Unlike adaptive damping,

Citroen's

famous Hydractive suspension is fast-reacting, can vary individual

axles'

spring rate and damping rate. Let's see how it works:

The Hydractive, which

appeared

in the XM as optional equipment since 1989, was based on the company's

traditional "Hydropneumatic suspension". The latter has a large sphere

at the top of each shock absorber. Within the sphere there are 2

compartments

filling with compressed air and high-pressure fluid respectively,

separated

by an elastic barrier. The gas acts as conventional suspensions' spring

while the fluid acts as damper. Shock from the wheel transmit via the

fluid

into the elastic barrier, than compress into the gas compartment. The

gas

absorbs the energy and release back to the fluid, which smooth the

reaction

by its damping effect. Remember, in the "Hydropneumatic suspension"

there

is no spring and damper. The sphere does the jobs of both.

Now comes to the

sophisticated

Hydractive suspension. It still employs the spheres at each corner, but

added with an extra sphere (central sphere) at each of the axles,

linking

by fluid between the spheres at left and right wheel. The front and

rear

central spheres also link each other. In other words, the front and

rear,

left and right suspensions are all interconnected by high-pressure

fluid.

With the addition of

central

spheres, the total volume of gas and fluid increases. Therefore the

suspension

can provide softer spring and damping rate that requires by comfortable

ride. Moreover, like the conventional Hydropneumatic suspension, the

fluid

can flow from one wheel to another, one axle to another, thus further

smoothen

the ride.

When the car need

stable

handling and roll resistance, valves in the central spheres close, thus

isolating the wheel's spheres. As the volume of gas and fluid has been

reduced, stiffer spring and damping rate are obtained.

The setting is not

just bounded

to "soft" and "hard" only, since there are many valves associated in

the

central spheres. The more valves close, the stiffer the suspension

becomes.

In fact, Citroen added more valves to the Hydractive 2 system in 1993

in

order to create more level of setting and smoother transition between

soft

and hard.

What made the

Hydractive

so effective is its fast-reacting brainpower. Powerful computer

analysis

the data acquired by speed, g-force, throttle, brakes and gearbox

sensors,

then decide the most suitable setting and activate the valves via

solenoid

and sophisticate power electronics.

Because the

energisation

of the solenoid valves takes as long as half a second while

de-energisation

need merely 2 milliseconds, Citroen use the de-energisation to actuate

the closure of valves, thus making the change from soft to hard setting

far quicker than vice versa. This is very logical, as we always need

stiff

suspensions as soon as we start driving hard. We don't need to enjoy

comfortable

ride as soon as we ease off the throttle.

Citroen Xantia's Hydractive 2 ( Activa

)

Citroen C5's Hydractive 3

The third generation of

Hydractive

suspension is relatively simple to explain. The system, introduced in

C5

in early 2001, was a refinement of the previous generation. Unlike

Activa

(Hydractive 2), it does not have the active anti-roll bar which was

criticized

by some as feeling unnatural. Instead, it added variable ride height

function,

which is easily to implement in hydraulic suspension. By adding or

removing

fluid in the suspension, ride height can be varied. At speed, ride

height

will be decreased to reduce aerodynamic drag and improve stability. By

lowering the front end a few mm more than the rear also introduce some

more downforce (well, may be less lift). At low speed, ride height will

be increased to provide more bump travel and avoid contacting with

ground

obstacle. Off road at really low speed the ride height will be adjusted

to maximum.

The best of the

Hydractive

3, however, is the recalibration of the software system to provide

firmer

yet smoother cornering without the nervous reaction of the previous

generations.

Moreover, by reshaping the gas-fluid spheres, the system becomes more

durable,

without needing maintenance until 200,000 km or 5 years.

As before,

electronics sensors

monitor steering action, brake pedal pressure, engine speed etc. to

know

the driver's driving style. If it sense a leisure driving style,

electromagnetic

valves will be opened thus link the center sphere of each axle with

left

and right suspension spheres, hence increasing volume of gas and fluid

thus provides softer spring and damping rate. In contrast, for sporty

driving

style the center sphere will be isolated from suspension spheres thus

increase

spring and damping rate, providing a firmer ride and better body

control.

Active Roll Control

Citroen Xantia's Activa

|

Xantia

Activa has even

more spheres. Note the additional sphere incorporated in the front

anti-roll

bar. |

Compare with XM's

Hydractive

suspension, Xantia's Activa system has an additional anti-roll function.

Hydractive reduce

body roll

by stiffening the spring and damper in the price of ride. If it could

stiffen

the suspensions to as hard as Formula One racing cars, it would have

achieve

near-zero body roll under hard cornering. However, because we need an

acceptable

level of ride comfort in a road car, we cannot do that. Therefore

Citroen

developed the active anti-roll bar, added it to the Hydractive and

becomes

Xantia's Activa system.

Based on the

Hydractive,

Activa incorporates a gas-filled sphere in the middle of the anti-roll

bar. The anti-roll bar is unusually thick at a diameter of 28 mm up

front

and 25 mm at the rear. The sphere acts as a cushion, thus allows the

anti-roll

bar to be twisted more easily. Therefore, the 28 mm anti-roll bar

actually

performs like a 23 mm one, thus offer less anti-roll function for

normal

drive.

When the car goes

into a

corner quickly, computer detects body roll thus close the valves in the

sphere. This isolate the gas in the sphere thus eliminate the cushion

effect.

The anti-roll bar thus resume its original stiffness, acting exactly as

a 28 mm anti-roll bar.

It doesn't end here.

If the

lateral acceleration is so strong that body roll continues to exceed

0.5

degree, fluid will be fed into 2 hydraulic rams at the front and rear

which

adjust the anti-roll bars to keep cornering level.

At any time, Xantia

Activa

rolls at most half a degree. This make it not only spectacular to look

at, but also improve cornering speed. French magazine L'Automobile

tested

a Xantia Activa on skidpad and measured an amazing 0.94 g lateral

acceleration.

This compares competitively with many supercars - NSX managed 0.93 g,

Ferrari

512TR 0.92 g, Toyota Supra 0.95 g and Ferrari F40's 1.01 g. This is

even

more impressive if you consider the Xantia wears just 205/55R15 tyres !

Most cars in its class manage around 0.8 g only !

<<

Xantia Activa cornering without roll

<<

Xantia Activa cornering without roll

Mercedes' Active Body Control

(ABC)

Compare with

Citroen’s Activa,

Mercedes’ ABC (Active Body Control) seems rather simple. ABC is a

purely

active roll control device. It can vary spring rate but not damping,

unlike

Citroen’s Hydractive or Activa. Therefore it is not classified as

semi-active

suspension. However, the application in the new CL coupe demonstrate it

helps achieving a stable and fluent cornering. It also saves the need

of

anti-roll bar.

New CL

with ABC versus

old CL

New CL

with ABC versus

old CL

The mechanical is

quite

simple. Each of the four wheels rides on a thick strut which

incorporate

both spring and damper into a single unit. The damper is in the core of

the strut, surrounding by the coil spring which is topped by a fluid

chamber.

When the chamber is fully filled with fluid (supplied from hydraulic

pump),

the spring is pushed towards the wheel and compressed, thus resist body

roll. On the contrary, if the fluid chamber is emptied, the spring will

be released towards the top of the strut, thus become softer.

ABC is not very

fast-reacting

- the maximum frequency of change is just 5 Hz, because the filling of

fluid takes time - but that’s more than enough for dealing with body

roll.

|

|

Lotus' fully active

suspension

Unquestionably, active

suspension

is the most ideal suspension. A true active suspension has

double-acting

hydraulic actuator instead of springs and dampers. As tyres meets bump,

the wheel's acceleration and vertical load is transmitted to a computer

which calculates the required wheel velocity and displacement and sends

control signal to the actuator. As the dialogue is conducted hundreds

of

times a second, the wheel accurately follows the contour of a bump,

thus

protecting the body structure against unwanted forces.

When riding on a

bump, Active

suspension, Hydractive suspension and Adaptive damping react very

differently.

The following explain how they "think":

Adaptive damping : "A

shock

encountered ! Another shock ! Again another .... Oh, it seems that the

car is running slowly on bumpy road, let me change the damping rate to

soft setting."

Hydractive suspension

: "A

shock encountered ! I must be riding on a bump. As the car is running

slowly,

I must change the suspension to soft-intermediate setting .... OK, I've

changed .... Oh, the body still accelerating upward ! This means the

suspension

is still too hard. I should have changed to soft setting ! It's too

late.

The bump has already been passed."

Active suspension :

"A shock

is encountered ! I start riding on a bump. Vertical acceleration sensor

and speed sensor tells me the bump is quite high. OK, signal the wheel

actuator to compress 10 mm progressively .... sensors tell me it's not

enough. Well, this time compress another 8 mm and see what's going on

....

6 mm this time .... 4 more mm .... 3 .... 2 .... 1 .... Wow ! I am

riding

on the peak right now ! Start releasing the actuator for 1 mm .... 2 mm

.... 4 mm .... 7 mm .... 10 mm .... Return to flat ground ! Well done !"

As you can see,

active suspension

is simply a perfect concept. Theoretically it could absorb all the

shock

while maintaining the car body stable. Engineers dreamed for it long

ago,

but it was Lotus that put it into reality.

Lotus started

researching

active suspension in 1981, originally intended to equip its Formula One

racing cars. The active F1 ran in Brazil and Long Beach '83 in the

hands

of Nigel Mansell. Despite of lacking competitiveness, it proved that

active

suspension could withstand hard use at 180 mph and 3 g lateral

acceleration.

The development team went back to drawing board and did more test to

improve

the software. It was not raced again until 1987, when the Honda-powered

99T won 3 races in the hands of Ayrton Senna.

However, the active

suspension

did not offer sufficient advantage in F1 racing. Theoretically, it

could

raise cornering speed considerably. ("Cornering at 200mph" used to Team

Lotus's slogan when defending this technology.) But on the down side,

its

hydraulic pump consumed horsepowers. I don't have the exact figure, but

years later Lotus told us the active suspension in its Excel

development

car consumed 4 - 4.5 hp on smooth road and up to 9 hp on rough road.

Worst

of all, Team Lotus did not get specially developed tyres to extract its

potential. As the active suspension reduced tyre's slip angle, the

tyres

generated insufficient heat to attain the necessary working temperature.

Just after the F1

debut in

the 1983 season, Lotus Engineering started developing the active

suspension

technology for production car use. It used the Esprit as the

development

platform. Like the racing car, the hardware - hydraulic actuators -

came

from aerospace industry, where active suspension was used in advanced

jet

engines. According to the engineers involved, the most crucial part was

the software rather than hardware. They had to road test a lot to

acquire

the necessary data in order to write the program.

The first 2

generations were

springless, but the Mk III and Mk IV system, which were equipped in the

Excel development cars, had springs as back up in case the active

system

break. The software was gradually improved. British magazine Fastlane

tested

them twice, once in the '87 Mk III and then in the Mk IV two years

later.

In the latter it reported significant improvement in ride quality and

body

control. It also expressed full optimistic that the system would go

into

mass production within a few years, probably under the name Volvo,

Chevrolet

or Mercedes-Benz, as they all had been consulting Lotus.

This did not come

true. Until

today I haven't seen any sign that car makers are going to put a fully

active suspension into production. The main reasons, I guess, are

likely

to be cost, power consumption and reliability. The only successful

application

was still in motor racing - between 1992 and 1994, F1 championship were

dominated by the active Williams and Benetton. Meanwhile, DTM series

also

saw active suspension's superiority in Mercedes C-class and Opel

Calibra.

Perhaps it was too superior, FIA eventually banned it.

The last time I heard

Active

suspension was in 1995 (?), when Lotus showed the Esprit SDIII

development

car. After that, the automotive world seems to have forgotten the most

ideal suspension ever appeared.

Some people was

misled by

Nissan Infiniti Q45a of 1990. Nissan called the car's suspension as

"Fully

Active" but that was actually a lie. It was just an adaptive damping,

with

conventional coil springs taking care of compression and an hydraulic

device

dealing with rebound.

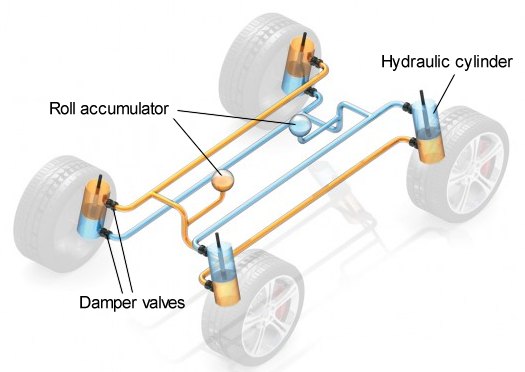

Tenneco Kinetic Suspension, e.g. McLaren PCC

Tenneco Kinetic suspension is brought to the world's

attention by McLaren MP4-12C, on which the system is called PCC

(Proactive Chassis Control). The latter is the technology's first

application on production performance cars. It shows an amazing

combination of smooth ride and excellent body control. Here we are

going to see how it works.

The Kinetic suspension was invented by Australian engineer Chris

Heyring. American component maker Tenneco acquired its patent in the

late 1990s and developed it for production. Early adoptors include

Citroen C4 rally car (before WRC banned the tech) and Lexus GX470 SUV.

This suspension utilizes hydraulic and gas pressure to provide active

anti-roll function, saving the need for conventional anti-roll bars

thus improving ride comfort. It may also provide adaptive damping,

therefore it is regarded as semi-active suspension.

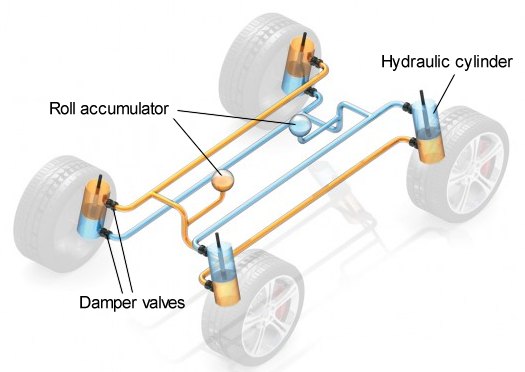

The hardware of Kinetic suspension looks similar to Citroen's

Hydractive suspensions, but it differs in details and principles. In

place of conventional dampers are four hydraulic cylinders, each

contains a compression chamber and an expansion chamber. They are

interconnected in a way that the compression chambers on the right

wheels link to the expansion chambers on the left wheels, vice versa.

Besides, front and rear wheels are connected. The picture below should

give you a clear idea:

There are two "roll

accumulators", each locate at one of the hydraulic circuit. The

accumulator contains oil (from the circuit) and pressurized gas,

separating by a flexible membrane (like Citroen's suspensions).

Electronic control unit can vary the gas pressure. If it pumps more gas

into the accumulator, more oil will be pushed back to the circuit. If

it releases gas pressure, more oil will be allowed to flow into the

accumulator.

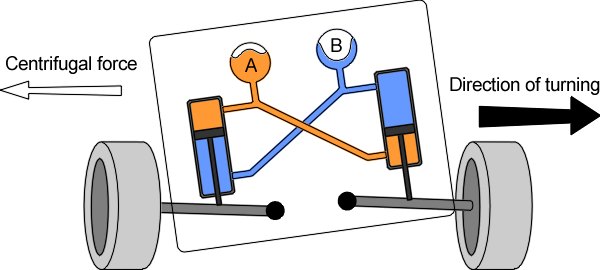

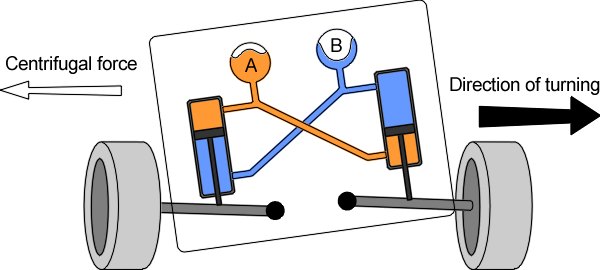

Now see my exclusive illustration below. In case the car steers quickly

to one side, centrifugal force is built up at the opposite side,

leading to body roll. As a result, the inside wheel dips and the

outside wheel compresses. This leads to the orange circuit attains

increased pressure from both cylinders, driving more oil into

accumulator A. On the contrary, the blue circuit attains reduced

pressure from both sides, therefore oil flows from accumulator B to

both cylinders.

Now, if we increase the gas

pressure in accumulator A, oil will be pushed back to the cylinders,

pressing down the outside wheel and lifting up the inside wheel, thus

eliminating body roll. The higher gas pressure injected, the stronger

it resists body roll. As you can see, each roll accumulator is

resonsible for regulating body roll to one direction.

What if the car is not cornering, but hitting a bump on the road ? Oil

from the compressed wheel will flow towards other wheels, thus the

suspension absorbs the bump comfortably. In contrast, conventional

suspensions with anti-roll bars always return a stiff ride on road

irregularities.

How does the Kinetic suspension achieve adaptive damping ? Turn back to

our first picture, you can see the oil flows in/out the hydraulic

chambers via a valve, whose degree of opening is adjustable. This

ensure the ECU can control the speed of oil flow, hence the damping

rate.

Copyright©

1998-2011 by Mark Wan

AutoZine

Technical School

Return

to AutoZine home page

<<

Xantia Activa cornering without roll

<<

Xantia Activa cornering without roll