|

AUTOZINE TECHNICAL SCHOOL

Cam-changing VVT Honda pioneered road car-used VVT in the

late 1980s with its famous VTEC system (Valve Timing Electronic

Control). First appeared in Civic, CRX and NSX, then became standard in

most production models.

You can see the VTEC mechanism as 2 sets of cams having different shapes to enable different timing and lift. One set operates during normal speed, say, below 4,500 rpm. Another substitutes at higher speed. Obviously, such layout does not allow continuous change of timing and lift, therefore the engine performs modestly below 4,500 rpm but above that it will suddenly transform into a wild animal. This system does improve peak power - it can raise red line to nearly 8,000 rpm (even 9,000 rpm in S2000), just like an engine with racing camshafts, and increases top end power by as much as 30 horsepower for a 1.6-litre engine !! However, to exploit such power gain, you need to keep the engine boiling at above the threshold rpm, therefore frequent gearchange is required. As low-speed torque gains too little (remember, the cams of a normal engine usually serves across 0 to 6000 rpm, while the "slow cams" of VTEC engine still needs to serve across 0 to 4500 rpm), tractability is unlikely to be too impressive. In short, cam-changing system is best suited to sports cars. Honda has already improved its 2-stage VTEC into 3 stages on some models. Of course, the more stage it has, the more refined it becomes. It still offers less broad spread of torque than other continuously variable systems. However, cam-changing system remains to be the most powerful VVT, since no other system can vary the Lift of valve as it does.

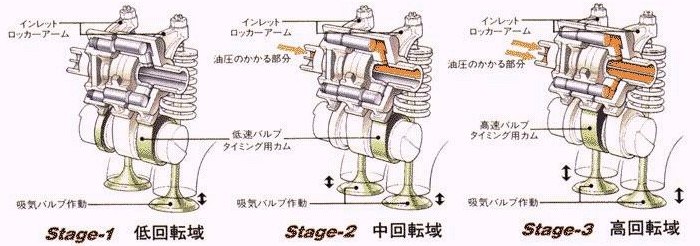

Example: Honda 3-stage VTEC  Honda's latest 3-stage VTEC has been applied in Civic SOHC engine in Japan. The mechanism has 3 cams with different timing and lift profiles. Note that their dimensions are also different - the middle cam (fast timing, high lift), as shown in the above picture, is the largest; the right hand side cam (slow timing, medium lift) is medium sized; the left hand side cam (slow timing, low lift) is the smallest. This mechanism works like this : Stage 1 (low speed) The 3 pieces of rocker arms move independently. Therefore the left rocker arm, which actuates the left inlet valve, is driven by the low-lift left cam. The right rocker arm, which actuates the right inlet valve, is driven by the medium-lift right cam. Both cams' timing are relatively slow compare with the middle cam, which actuates no valve now. Stage 2 (medium speed) Hydraulic pressure (painted orange in the picture) locks the left and right rocker arms together, leaving the middle rocker arm and cam to run on their own. Since the right cam is larger than the left cam, those connected rocker arms are actually driven by the right cam. As a result, both inlet valves obtain slow timing and medium lift. Stage 3 (high speed) Hydraulic pressure locks all 3 rocker arms together. Since the middle cam is the largest, both inlet valves are actually driven by that fast cam. Therefore, fast timing and high lift are obtained in both valves. Another example - Nissan Neo VVL Very similar to the Honda system, but the right and left cams have the same profiles. At low speed, both rocker arms are driven independently by those slow-timing, low-lift right and left cams. At high speed, 3 rocker arms are locked together such that they are driven by the fast-timing, high-lift middle cam. You might think it must be a 2-stage system. No, it is not. Since Nissan Neo VVL duplicates the same mechanism in the exhaust camshaft, 3 stages could be obtained in the following way: Stage 1 (low speed): both intake and exhaust valves are in slow configuration. Stage 2 (medium speed): fast intake configuration + slow exhaust configuration. Stage 3 (high speed): both intake and exhaust valves are in fast configuration. |

||||||||

|

||||||||

| Copyright© 1997-2011 by Mark Wan @ AutoZine |