|

AUTOZINE TECHNICAL SCHOOL

Variable Valve Timing (VVT) Basic Principles After multi-valve technology

became standard in engine design, Variable Valve Timing becomes the

next step to enhance engine output, no matter power or torque.

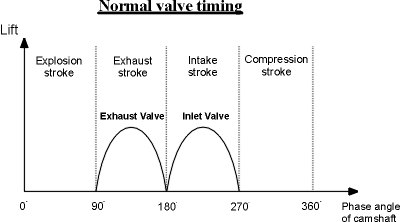

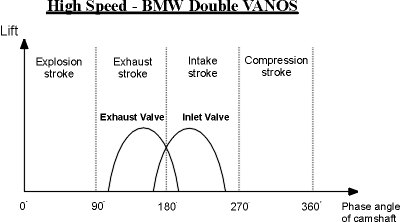

As you know, valves activate the breathing of engine. The timing of breathing, that is, the timing of air intake and exhaust, is defined by the shape and phase angle of cams. To optimise the breathing, engine requires different valve timing at different speed. When rev increases, the duration of intake and exhaust stroke decreases so that fresh air becomes not fast enough to enter the combustion chamber, while exhaust gas becomes not fast enough to leave the combustion chamber. Therefore, the best solution is to open the inlet valves earlier and close the exhaust valves later. In other words, the Overlapping between intake period and exhaust period should be increased as rev increases.   Without Variable Valve Timing

technology, engineers used to choose the best compromise timing. For

example, a van may adopt less overlapping for the benefits of low speed

output. A racing engine may adopt considerable overlapping for high

speed power. An ordinary sedan may adopt valve timing optimised for

mid-range so that both low-speed drivability and high-speed output

will not be sacrificed too much. No matter which one, the result is

just optimised for a particular engine speed.

With Variable Valve Timing, power and torque can be optimised across a wider rpm band. The most noticeable results are: - The engine can rev higher, thus raises peak power. For example, Nissan's 2-litre Neo VVL engine produces 25% more peak power than its non-VVT version. - Low-speed torque increases, thus improves drivability. For example, Fiat Barchetta's 1.8 VVT engine provides 90% peak torque between 2,000 and 6,000 rpm. Moreover, all these benefits come without any drawbacks. Variable Lift In some designs, valve lift can

also be varied according to engine speed. At high speed, higher lift

quickens air intake and exhaust, thus further optimise the breathing.

Of course, at lower speed such lift will generate counter effects like

deteriorating the mixing process of fuel and air, thus decreases output

or even leads to misfire. Therefore the valve lift should be variable

according to engine speed.

VVT's benefit to fuel consumption and emission EGR (Exhaust Gas Recirculation) is a commonly adopted technique to reduce emission and improve fuel efficiency. However, it is VVT that really exploits the full potential of EGR. In theory, maximum overlap is needed between intake valves and exhaust valves’ opening whenever the engine is running at high rev. However, when the car is running at medium speed on highway, in other words, the engine is running at light load, maximum overlapping may be useful as a means to reduce fuel consumption and emission. Since the exhaust valves do not close until the intake valves have been open for a while, some of the exhaust gases are recirculated back into the cylinder at the same time as the new fuel / air mix is injected. As part of the fuel / air mix is replaced by exhaust gases, less fuel is needed. Because the exhaust gas comprise of mostly non-combustible gas, such as CO2, the engine can run at the leaner fuel / air mixture without the risk of misfire. |

||

|

||

| Copyright© 1997-2011 by Mark Wan @ AutoZine |