|

AUTOZINE TECHNICAL SCHOOL

4-Wheel Drive Electric

4WD

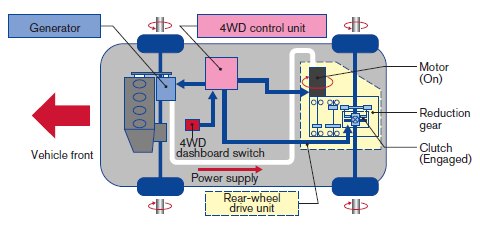

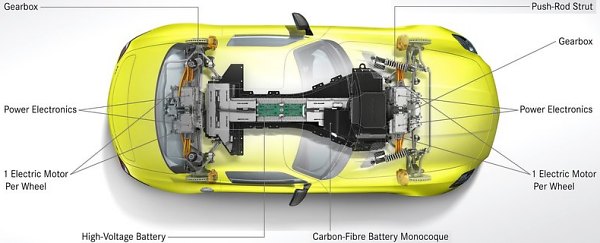

The last lesson of our 4WD course is also the easiest to learn, because it doesn't involve any complicated mechanical ideas... Electric 4WD is increasingly popular these days thanks to the rise of hybrid and electric cars. However, throughout its short history there are only a few representatives worth mentoining: Nissan e-4WD - Nissan March / Cube (2002) As far as I can remember, Nissan e-4WD was probably the earliest electric 4WD system put to mass production. It was launched in 2002 on the Japanese market March (i.e. Micra) and Cube as option. That was well before the popularity of hybrid and electric cars. Make no mistake, these cars were neither hybrids nor EVs (they had no battery to store energy). They just tried to offer the benefit of 4WD without the excessive cost / weight / size penalties of conventional 4WD hardware. Their primary objective was not to improve handling or driver appeal but to deal with snowy roads in winter, so they were quite popular in Northern Japan. The system was actually developed and supplied by local electric giant, Hitachi.  The e-4WD system manages to save weight and space because it has no mechanical connection between engine and rear axle. The front wheels are driven by the engine as usual, while the rear wheels are driven by an electric drive unit which is mounted under the boot and between the rear wheels. The electric drive unit consists of a small electric motor, reduction gears and a differential/clutch unit. It is supplied by an engine-driven generator via cables. As it eats power from the engine, the electric propulsion does not add any performance, unlike the case of hybrid cars. What triggers the engagement of electric rear axle is a 4WD switch on the dashboard. As seen, this is a very simple and low cost 4WD system. It takes little space thus can be easily fitted into front-wheel-drive small cars. In particular, there is no need to modify the chassis to make space for a transmission tunnel. This make it especially attractive to small FWD cars like the March and Cube. PSA Hybrid4 - Peugeot 3008 Hybrid4 (2011) Entering the era of hybrid cars, Peugeot 3008 Hybrid4 was probably the first to use electric motor to realize 4WD. That might not be its original intent, but for packaging reasons it is admittedly easier to place the electric drive hardware under the boot and let it drive the rear wheels directly. A 2.0HDi turbo diesel engine drives the front wheels as usual, while a 27 hp electric motor provides extra push at the rear axle. Sitting next to the motor are the reduction gears, inverter, power electronics control module and NiMH battery pack. All are placed under the rear seat and boot floor so that not to reduce luggage space.  The participation of electric motor depends on driving mode: ZEV: only the electric motor provides propulsion, so the car is driven only by rear wheels (but slowly). Auto: computer decides the combination of engine and motor power to optimize fuel economy. Sport: uses sportier gearshift pattern to optimize performance of engine, while motor boosts acceleration. 4WD: whenever the car slides, the motor is engaged to enhance traction. The Hybrid4 is also used by the flagship models of Peugeot 508 and Citroen DS5, but overall it is not very popular, blame to the high cost. Compared with other hybrid cars, it is a lot more expensive to build, partly because of the extra driving gears and axles it needs, and partly because the turbo diesel engine is already more expensive than the petrol engines of its rivals. Individual motor drive - Mercedes SLS Electric Drive (2013) The best thing about electric 4WD is freedom of packaging. As electric motors are compact and free of mechanical linkage, you can place them anywhere in the car. You may even use one motor to drive each wheel directly, saving the need of front differential, center differential, rear differential and propshaft. This realizes not only a variable torque-split 4WD but also the most versatile torque vectoring ever seen, because you can assign whatever torque to each wheel at will.  Mercedes SLS Electric Drive is the first car to put such an individual motor drive system into production, albeit a very small scale production. To keep unsprung weight low, it skips in-wheel motors for 4 motors mounted inboard, each drives a wheel through its own reduction gears. The monstrous total output of 751 horsepower is well managed by the traction/stability/torque vectoring control, which can be easily implemented by power electronics and software. It shows the way for future performance cars. Yes, this is the ultimate form of 4-wheel drive! Ridiculously, Dr. Ferdinand Porsche did built a 4WD electric car with individual motors in 1900. It makes us wonder why we wasted a century, countless of money and manpower to develop mechanical solutions like LSDs, viscous couplings, electrohydraulic multi-plate clutches and active differentials just to serve the same purpose! |

||

| Copyright© 1997-2016 by Mark Wan @ AutoZine |