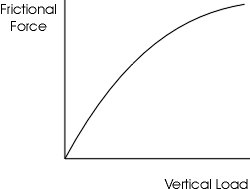

Look at the following graph. It illustrates the Grip - Load characteristic of a typical tyre.

Therefore the total grip decreases as weight transfer occurs. The more weight transfer, the less the total grip becomes.

Now can have some conclusions : to maximize the cornering grip, we must minimize the weight transfer. We can achieve this by lowering the CG, by reducing the weight of the car or by enlarging the track width. The first could be implemented by placing the heavy engine and transmission as low as possible, by using a wide V-angle or even boxer engine, and by lowering the seats. The second can be implemented by using lightweight materials and better chassis structure, and reducing the size of the car, but this seems to conflict with the third method. Therefore I don't recommend to increase the track width to as wide as Lamborghini Diablo. It won't help making the car nimble too. Another advantage of weight reduction is obvious: quicker to accelerate and to stop.

These are no secret. Any one interested in motor racing already knows them.

Weight versus Downforce

But then you may ask a question: reduce the car's weight also reduce the grip generated by the tyres, so what's the advantage ?Firstly, because the car is lighter, centrifugal force acted on it is smaller. In theory the reduced grip could exactly withstand the reduced centrifugal force. Secondly, we could use aerodynamic downforce to increase the grip without increasing the centrifugal force. As a result, the car can corner faster.

4. Weight Transfer due to body roll

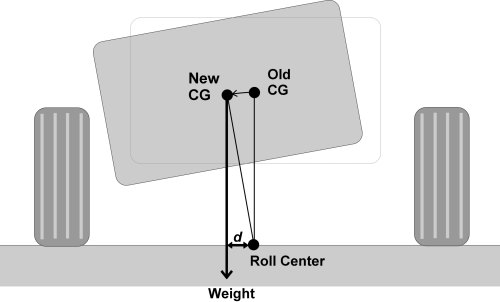

Body roll also introduces weight transfer thus reduction of total grip. Let's see the following drawing :

The lateral displacement of center of gravity (CG) is d. If we again use the Boxster example (track width 1600 mm, height of CG 500 mm, weight 1250 kg), if it rolls 10 degrees when cornering, d will be 500 x sin10° = 86.8 mm. Then the load of the outside wheels can be calculated as: ( 1250 x ( 800 + 86.8 ) ) / 1600 = 693 kg while the inside wheels take 557 kg. So there is 68 kg weight transfer. Although it is not a great amount compare with the weight transfer due to lateral acceleration, its influence should not be ignored because camber change exists in this case.

We want to keep the body roll to an adequate level. We can use stiffer spring and anti-roll bar to reduce roll in the price of ride comfort. We can move the roll center, which is determined by the suspension geometry, as close to the CG as possible so that the roll moment is largely reduced, but this has a very bad drawback - a large jerking force will be generated and jerk up the body thus raise the CG. Alternatively, we could leave the body roll alone and try to lower the CG, so the weight transfer is also reduced.

After all, I don't recommend to eliminate body roll, since it is an important signal to tell us how well the car enters a corner and how close it approaches its limit. Body roll is a kind of feedback.

5. Four-Wheel Drive

Finally, 4WD can maximize the total grip of the car, both in straight line and cornering. The former case is easier to understand: compare with RWD and FWD cars, 4-wheel drive cars distributed less tractive force to each of its driving wheels, so it is less likely that the tractive force exceed the frictional force generated between tyres and ground. In other words, the driving wheels are less likely to slide. However, since we are talking about handling, straight line grip is not our interest.For cornering grip, whose direction is perpendicular to the wheel's tractive force, the above mentioned theory is completely useless. The actual theory is quite complicated, it requires the concept of Slip Angle, which will be introduced in later sections. We will continue this discussion later.