|

AUTOZINE TECHNICAL SCHOOL

Automatic Transmission Overview

When I first wrote this section in 1999, I was pessimistic about the future of automatic transmissions. Traditionally, automatics were slower responding, thirstier and heavier than manual transmissions. When automated manual and especially twin-clutch gearbox emerged, there seems to be few reasons for automatic to survive. Somehow, automatic not only lives healthily today but it gets even more popular. Many premium, luxury or even performance cars use exclusively automatic transmissions. This proves that the progress of automatic transmission technology has far outpaced that of manual. In the past, we said automatic typically added 25-30 kg over manual box. Now the gap is narrowed to 10-15 kg in many cases. Moreover, most of the latest automatic now have 8 or more forward gears, whereas 6 is still the norm of manual. This enable them to shift faster while improving fuel efficiency. Most important, the control logic of automatic has progressed so much that human struggles to match. Automatic transmission was first developed by the engineers of Cadillac in the 1930s. It was applied to various mass production cars of General Motors from 1939, including Oldsmobile, Buick, Cadillac and Pontiac. GM trademarked it "Hydra-Matic" as, unlike manual transmission, it used hydraulic to make gearshift automatically. This definition still applies today. When we say automatic transmission, we mean those using planetary gears and hydraulic to implement gearchange automatically. They may include manual control, but the mechanism is shift-by-wire rather than mechanical. Nearly all automatic boxes use torque converter instead of clutch as a means connecting the engine and gearbox, which contributes to a seamless transition, but a variant by Mercedes called MCT uses a multi-plate clutch instead. Computerized The first wave of automatic revolution was the computerization in the 1980s. Modern microprocessor and memory allow the gearbox to offer multiple shift patterns for different situations, for example, Economy, Sport and Winter (Snow) were the most popular choices then. In Sport mode, the gearbox upshifts at higher engine speed to make better use of the power band, thus improves acceleration. On the contrary, choosing Economy mode will ease the engine thus enhance smoothness, quietness and fuel economy. As development continued, the ECU got learning function as well (some used Fuzzy logic), capable to memorize the driving habit of the driver by reading throttle behaviour, rev, steering, g-force etc. and adapt the shift patterns to suit the driving style. They can also sense the driver's intention and automatically select the most suitable mode. Manual override - e.g. Porsche Tiptronic Launched in 1990, Porsche Tiptronic was the first automatic transmission with manual override put into mass production. It debuted on the 911 as option, then expanded to 968 and other models. It was also licensed to Audi and Mitsubishi for production. Later on, Honda, BMW, Chrysler and Toyota developed their own versions using the same concept. The Tiptronic was developed jointly by Porsche, ZF and Bosch. Porsche originated the idea, while ZF built the transmission and Bosch was responsible for its electronics. The original Tiptronic was based on a 4-speed automatic gearbox with torque converter. It could work purely as an automatic, but in case the driver wanted to take control, he could push the shifter sideway into a slot with + and - positions to control upshift and downshift respectively. This let the driver feel more engaging, but the gearshift time was actually no faster than an automatic working in Sport mode. After all, the Tiptronic was essentially an automatic, just with a different driver interface.

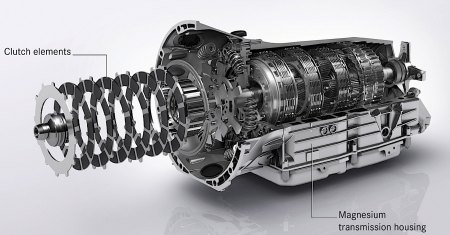

In 1995, a new version called Tiptronic S added fingertip control button on the steering wheel spoke, allowing the driver to shift without losing concentration from the road. Like contemporary automatics, the Tiptronic's auto mode could smartly select from 5 shift patterns to suit different driving style. For example, frequent full-throttle engagement and brisk release of throttle indicate a sporty driving style, thus it would select the sport program. In manual mode, if the engine redline was exceeded, the electronic control would upshift automatically to protect the engine. More and more ratios When I started watching cars in the mid-1980s, most automatic transmissions had 4 forward gears. Some even had only 3. No wonder automatic was seen as inferior to manual in both performance and fuel economy, thus it was used mostly on luxury cars. As time goes by, more and more ratios are added. 5-speed became the norm in the 1990s, then ZF launched the first 6-speed auto on BMW 7-Series E65 in 2001. Brilliantly, despite the more ratios, the ZF 6HP was 13% lighter than the outgoing 5HP and used 30% fewer components. The closer ratios and wider ratio spread (i.e. the ratio between the lowest and highest gear ratios) enabled it cut fuel consumption by 5%. It changed the landscape of the market, turning many luxury and premium cars into automatic-only, and eventually sold 7 million units in its 13-years lifespan. However, the chase for more gears did not stop there. Mercedes 7G-Tronic lifted the bar to 7 ratios in 2003, and Aisin rewrote the record to 8-speed in 2006 (first used in Lexus LS460). ZF responded to its challengers with 8HP in 2009, which cut weight and fuel consumption by another 3% and 6% respectively from 6HP. As car makers chased for reducing fuel consumption, even more ratios followed. In 2013, ZF built the first 9-speed automatic for transverse-engined applications. It had a ratio spread of 9.8:1, and the top 4 ratios are overdrive to enhance cruising efficiency at any speeds! That's not the end of the story though, because Ford produced the world's first 10-speed auto in late 2016 (it was also offered to GM as part of the collaboration). Shortly afterwards, Aisin introduced a 10-speeder for Lexus, while Honda built a transverse 10-speeder whose ratio spread reached 10.1:1. By the time of writing, I heard that Honda is developing an 11-speed gearbox. How many will be enough? More ratios mean the engine could be working at optimum revs more of the time, benefiting both fuel economy and acceleration. It also allows the ratios to spread in a wider range, having a taller first gear and shorter top gear to achieve the best of both worlds. Nevertheless, as ZF said, the benefits diminish as more ratios are added. The more ratios, the more gearchange is needed. Although the smaller difference between adjacent ratios enables the gearchange to be speeded up (since rev-matching is quicker), there is still a limit. If too many ratios are used, the gearbox will spend more time in gearchange, outweighing the benefits. Evolution of ZF automatics

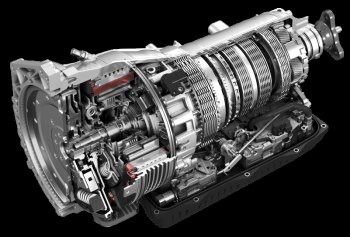

Performance edge As automatic transmission is controlled by computer, it is compatible with electronic launch control. Consequently, modern performance cars are usually quicker to accelerate off the line with automatic gearbox. Twin-clutch manual gearboxes still have an edge, because clutches are more responsive than torque converters, but automatic will leave conventional manual gearbox dead in standing start, since human cannot beat launch control. For example, the offiical 0-60 mph time of BMW M140i is 4.6 seconds with 6-speed manual or 4.4 seconds with ZF 8-speed automatic. The same goes for Chevrolet Camaro ZL1, which takes 3.7 and 3.5 seconds with manual and automatic respectively. Riculously, what used to be seen as a slower, comfort-oriented kind of transmission has become the performance choice! Not just standing start acceleration, sometimes automatic also beats manual on track. For example, the Alfa Romeo Giulia Quadrifoglio fitted with ZF 8-speed auto lapped Nurburgring Nordschleife in 7:32, 7 seconds quicker than the 6-speed manual clocked previously. The clever shift logic, the responsive gearshift and the 2 extra ratios help. Even though it might not match twin-clutch manual for ultimate speed, the gap gets remarkably narrow these days. Moreover, automatic transmission has a strong advantage in luxury performance car segment, since it is capable to handle a lot of torque. It is easier to adapt an existing production automatic to high-torque applications than designing a dedicated twin-clutch gearbox like that of Bugatti Veyron. Moreover, the automatic is always smoother shifting than twin-clutch gearbox in auto mode, so it suits the dual-purpose requirement of luxury performance cars very much. Fuel economy improved The fuel efficiency of automatic has improved markedly against manual. 3 decades ago, a Mercedes 190E returned 27.9 mpg with 5-speed manual transmission, while 4-speed auto was thirstier at 25.0 mpg (both were Autocar test data). Today, a BMW 320i auto returns 53.2 mpg on European combined cycle, beating the manual version's 51.3 mpg. On higher performance level, the aforementioned BMW M140i auto returned 39.7 mpg, beating the manual's 36.2 mpg. The same happens in America, where Cadillac ATS-V auto (20 mpg) beats manual (19 mpg) on EPA combined cycle. Apart from increased number of ratios and wider ratio spread, modern automatics have improved so much because of improved efficiency of hydraulics, clutches and the wider use of torque converter lock-up. Torque converter wastes power when it slips (the power is converted to heat). Modern automatics can lock up the torque converter at each of its ratios, leaving slippage to happen only during start up and gearchange, thus minimizing the energy loss in steady running. Besides, by using economy-oriented shift patterns in default mode, economy is enhanced further. As much as conventional automatic transmissions have improved, they still fail to match dual-clutch manual transmissions (DCT) for gearchange speed. This won't change as long as they employ torque converters. Torque converter uses spinning fluid to couple its two halfs, so the coupling won't be as quick as using a rigid media like clutch discs. In 2008, Mercedes introduced a new automatic transmission called MCT (Multi-Clutch Transmission) on SL63 AMG. It was derived from the company's existing 7G-Tronic automatic, but had the torque converter replaced with a multi-plate clutch pack.

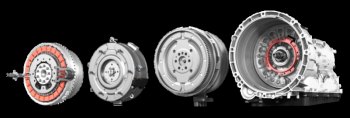

It is obvious why Mercedes opted for this unique solution instead of using DCT like its rivals. Firstly, it is cheaper to develop and build because it is based on the existing 7G-Tronic (unlike most other car makers, Mercedes always builds its own automatic transmissions). Secondly, also because of its 7G-Tronic origin, it has the same external dimensions thus could be fitted to all of the company's rear-wheel-drive cars without modifications. Thirdly, back then there were no production DCTs on the market capable to withstand the 465 lbft of torque from the AMG 6.2-liter V8. The 7G-Tronic handled that with ease. Lastly but not least, the MCT's gearchange is slicker than DCT can manage (if not as smooth as torque converter auto), thus it suits the character of Mercedes AMG. As hybrid and plug-in hybrid technologies become essential for car makers to comply with stringent CO2 emission regulations, the question is how to make them easy to be fitted into existing car platforms, and make them cost effectively enough for mass production. ZF found a clever solution: incorporate the electric motor-generator into its automatic transmission. Based on its longitudinal-mounted 8HP unit, a disc-shape electric motor is added to the front and within the transmission casing. It adds just 3cm to the length, so could be easily installed on most cars curently employing the 8HP, especially its fans BMW and Audi. No wonder we saw many hybrid cars of both firms feature almost the same hybrid design, such as BMW 330e, 530e and 740e, Audi A6 e-tron, Q5 e-tron and Q7 e-tron. BTW, Mercedes' hybrid cars also employ the electric components from the ZF unit, even though it uses them on its own automatic transmissions.

In fact, ZF was not the first to put this idea into production. Jatco supplied a similar 7-speed automatic transmission to Nissan Fuga Hybrid (Infiniti M35h) in 2010. It put a 68hp electric motor in place of the torque converter and added 2 clutches inside the transmission for disconnecting the motor and/or gearbox. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copyright© 1997-2017 by Mark Wan @ AutoZine |