|

AUTOZINE TECHNICAL SCHOOL

Engine Configuration and Smoothness Boxer

(horizontally-opposed) engines

All boxer engines, regardless of number of cylinders, achieve perfect balance because the movement of a piston is countered by the opposite movement of the corresponding piston in another bank. Of course, the more cylinders the less pulsation effect and the smoother the engine runs and sounds.  The boxer engine's center of gravity is also lower, benefiting the handling of the car. On the downside, it is too wide for good packaging. It cannot be fitted transversely in the engine bay like conventionally FF cars. Instead, it must be installed longitudinally, usually fore of the front axle/differential. For boxer 4-cylinder that won't be much problem, but in the case of boxer-6, the car could be a little nose-heavy. 8 or 12 cylinders would be a nightmare, but fortunately we have never seen such cars. Because of the packaging problems, only Porsche and Subaru still persist in using boxer engines. VR6, V5, W12 and W16 For a conventional V6, a Vee angle as narrow as 15° would have required extraordinarily large spray angle between split crank pins, hence special reinforcement. However, in contrast to many believes, the crankshaft of Volkswagen VR6 is more like that of an inline-6. It has 7 main bearings and independent crank throws for each cylinder (this is possible because VR6 is much longer than a conventional V6), thus it could avoid the crank pin problem. Don’t think a 15° V6 must generate a lot of vibration! On the contrary, the VR6 is inherently a well-balanced configuration because it is nearly identical to an inline-6, just differs from the latter by a very narrow angle separating each pair of 3 cylinders. As a result, it generates no end-to-end vibration like conventional V6s and is nearly as smooth as an inline-6.

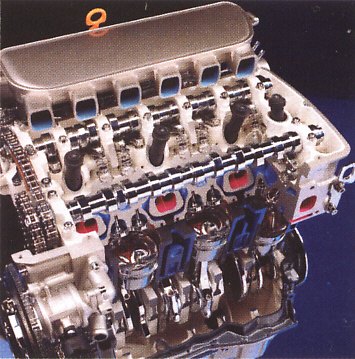

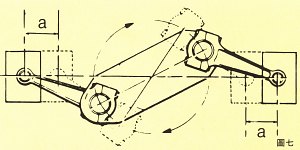

If VR6 is a version of inline-6, then W12 must be a version of V12. It is made by mating two VR6 at 72°. The corresponding cylinders in different banks share the same split crank pins. Thanks to the 72° V-angle, the splay angle between split crank pins can be so small that no additional reinforcement is required (see photo). You know, the short engine with 7 main bearings can hardly find space to add strengthened flying webs between the split crank pins. W16 is identical to W12 except that each bank consists of 4 cylinders instead of 3. In other words, it is made from 2 VR8 engines. The V5 is constructed by removing the first cylinder from an VR6. It seems to be unbalanced bank-to-bank, but with a very narrow V-angle and 5-bearing crankshaft, it works close enough to an inline-5 engine. A dual-mass flywheel and vibration damper take care of the remaining vibration. W8  For

installing to smaller cars, W8 was a logical development from W12.

However, W8 does not balance inherently, unlike W12. Although its

crankshaft has 5 main bearings and 4 crank throws like a conventional

V8, its short length means no space to fit large counter weights like a

conventional cross-plane V8. Therefore, it employs a flat-plane

crankshaft (probably the first for a non-exotic V8). Its crank throws

are machined extremely thin. The flat-plane crankshaft also means it

does not generate the "rumble bumble" noise like conventional V8s. For

installing to smaller cars, W8 was a logical development from W12.

However, W8 does not balance inherently, unlike W12. Although its

crankshaft has 5 main bearings and 4 crank throws like a conventional

V8, its short length means no space to fit large counter weights like a

conventional cross-plane V8. Therefore, it employs a flat-plane

crankshaft (probably the first for a non-exotic V8). Its crank throws

are machined extremely thin. The flat-plane crankshaft also means it

does not generate the "rumble bumble" noise like conventional V8s.You might remember, flat-plane V8 generates second order vibration like inline-4 engines. While high-performance V8s like Ferrari's or Lotus' can reduce such vibrations with shorter stroke, lightweight pistons and con-rods, the W8 could use neither because it was designed for Volkswagen Passat, which needed torque and reasonable costs. Moreover, while exotic sports car could put up with a certain level of vibration, a premium sedan like Passat W8 was not supposed to show anything regarded as unrefined. As a result, the only solution was to add counter-rotating twin-balancer shafts like inline-4 engines. This explains why the W8 was costly to build, and it was soon phased out. |

||||

| Copyright© 1997-2017 by Mark Wan @ AutoZine |