|

AUTOZINE TECHNICAL SCHOOL

Hydrogen Cars H2 + O2

= H2O. In my childhood I dreamed about a

car burning hydrogen and emitting only water vapour. That would be an

ideal solution to our air pollution problem (there were no such things

called global warming or greenhouse gas then). Somehow, it took 30

years to realize yet no one knows whether it will become popular on the

roads. There are mainly two kinds of hydrogen cars, one powered by a

hydrogen internal combusion engine, another powered by hydrogen fuel

cells and electric motors.

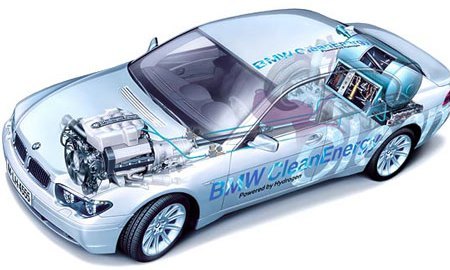

Hydrogen Engine BMW Hydrogen 7 (2006)

In 2006, there were no more than 100 hydrogen refilling stations in the world, and many of them were built for experimental purposes. That year, Mazda and BMW introduced their first hydrogen customer cars, RX-8 RE and Hydrogen 7, respectively. Considering the lack of infrastructural support and unknown reliability, no one would take the risk to buy a hydrogen-powered car. Therefore, they were leased to the customers in small quantities. The Mazda beat BMW to the market by a few months, but its Wankel engine was less relavant to the rest of the world, so let us skip it and concentrate on the BMW.

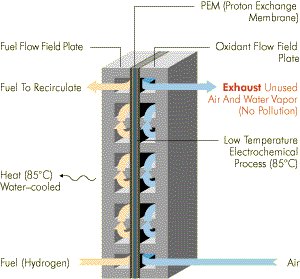

As seen, the hydrogen conversion offered no benefits except a green perception, but even the latter could be misleading. While the car produced no CO2, CO and HC, the combustion did produce small amount of NOx, especially at part load hence lean burn mode as the excess oxygen and nitrogen in air reacted together. Moreover, internal combustion engines are rather low in efficiency. The V12 of Hydrogen 7 had a thermal efficiency of 42%, comparable to diesel engines but a lot lower than hydrogen fuel cell (close to 60%). This means it wasted most energy through heat etc. Of course, the industry that produces hydrogen involves emission, so the more hydrogen the car consumes, the more pollution and greenhouse gas it indirectly emits. For all these problems, car makers opted to develop hydrogen fuel cell or battery electric cars instead. Hydrogen Fuel Cell A fuel cell is an electrochemical device

that generates electricity silently without involving combustion.

Hydrogen fuel,

which can be obtained from natural gas or methanol, and oxygen from the

air are electrochemically combined in the fuel cell to produce

electricity. Heat and pure water vapor are the only by-products.

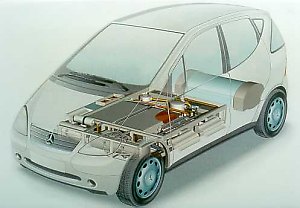

Mercedes NECAR 4 prototype

(1999)

The NECAR 4 was the fourth experimental

fuel cell car Mercedes-Benz developed. Unlike all its predecessors, it

was virtually production ready and offered practicalities like

conventional cars because it was derived from the production A-class.

Only the high cost of the fuel cell power unit, i.e. some £12000

versus gasoline engine’s £1900, prevented it from going into

production. The NECAR 4 was the fourth experimental

fuel cell car Mercedes-Benz developed. Unlike all its predecessors, it

was virtually production ready and offered practicalities like

conventional cars because it was derived from the production A-class.

Only the high cost of the fuel cell power unit, i.e. some £12000

versus gasoline engine’s £1900, prevented it from going into

production. Although it was already the most advanced fuel cell cars at its time, it did not performed quite as good as conventional cars. The 75hp fuel cell stack plus all the accessories like electric motor and high-pressure fuel tank added some 410kg over an entry-level A140, yet it offered 7 fewer horsepower. Although the electric motor produced constant torque at any rpm, it still failed to compensate the weight penalty. Top speed barely reached 90 mph, or 15 mph lower than A140. The A-class was a perfect platform for the fuel cell technology. Thanks to its sandwich structure, the large and heavy fuel cells could be installed under the floor, not only wasting no cabin space but also improving roll-resistance of the A-class. The electric motor and fuel tank were positioned near front and rear axle respectively. The high-pressure fuel tank stored liquid hydrogen at -253°C, offering a range of 450km. Later on, it was changed to compressed hydrogen gas tank (at 350 bar), lowering the range to 250km. The NECAR 4 would be developed into NECAR 5 and then the A-class and B-class-based F-Cell models. Mass production was once said slated for 2014, but that didn't happen. Although Mercedes is still committing to the development of hydrogen fuel cell, it has turned its focus to electric cars. Toyota Mirai (2015) Launched in 2015, Toyota Mirai was the world's first hydrogen fuel cell passenger car put into mass production – although mass production here means an annual volume of several thousand units only. Toyota worked hard to cut costs, such as sharing many components with its hybrid cars. Even so, the Mirai costs as much as a BMW 730d to purchase, yet it is actually sold at considerable losses. The car's fuel cell stack is made compact enough to be installed under the front seats. It consists of 370 cells and produces up to 155hp. Its power density of 2.7hp/kg is the highest currently in production. Toyota managed to cut its cost significantly by reducing the amount of platinum catalyst through nanotechnology and improved stack design. Electric power from the fuel cell stack is boosted to 650V, converted to AC and supply the front-mounted motor. To remove the heat generated by the fuel cell, the car sports 2 large radiators at either sides of the nose.  Under the rear seat and at the boot, there are two hydrogen fuel tanks. They are made of 3 layers – the inner is plastic seal, the middle layer is super-strong carbon-fiber reinforced plastics while the outer layer is impact absorbing glass-fiber reinforced plastics. They store the compressed hydrogen gas at 700 bar and protect against collision. The cylindrical tanks occupy a lot of space yet they carry only 5 kg of hydrogen. However, since hydrogen offers more energy by weight than gasoline, 5 kg is already good for a range of 300 miles in typical US and EU measurement, or 400 miles (650 km) in Japan. That is the biggest advantage over current generation of electric cars. Although the Mirai is still hardly cost competitive, it proves that hydrogen fuel cell cars can deliver practicality matching conventional cars yet without the range anxiety of electric cars. However, to replace gasoline and diesel cars they still need to cut costs massively, and the wide availability of hydrogen refilling stations will be cruicial. How Green is Hydrogen? How green is hydrogen cars? This question is not easy to be answered. Hydrogen-engined cars are obviously not very green because their internal combustion engines waste a lot of energy like conventional engines. Hydrogen fuel cell cars have significantly higher efficiency, but still their well-to-wheel emissions are hinged on the production method of hydrogen. Hydrogen can be produced by electrolysis of water. If the electricity comes from clean sources like wind or hydropower, the emission should be close to zero. If the electricity comes from coal power, then the emission could be very high. However, in reality, most of the world’s hydrogen is produced by reforming natural gas, whose primary ingredient is methane. This process mixes natural gas and steam at very high temperature (700-1000°C) and converts them to H2 and CO2. This is the most cost effective way to produce hydrogen, but it emits greenhouse gas and takes a lot of energy, which indirectly produces more greenhouse gas. The European Joint Research Centre (JRC) conducted a research in 2014 on the well-to-wheel emission on hydrogen fuel cell and other technologies. It covered the emissions resulted in the whole process, from oil production, hydrogen production, transportation and storage of fuel all the way to the generation of propulsion by the vehicle. Based on development trend of technologies, it forecasted by 2020 the well-to-wheel greenhouse gas emissions of different technologies as below.

* Assuming charged by EU-mix electricity, i.e. 33% nuclear, 31% coal and 21% natural gas, 3.5% oil and 12% renewable energy. As seen above, hydrogen fuel cell comes between EV and PHEV. However, in places using cleaner energy sources for electricity generation, such as California (60% natural gas, 30% renewable energy and 10% nuclear), hydrogen fuel cell cars struggle to keep up with EV and PHEV. |

||||||||||||||||||||||||

| Copyright© 1997-2017 by Mark Wan @ AutoZine |